Tailings

Tailings

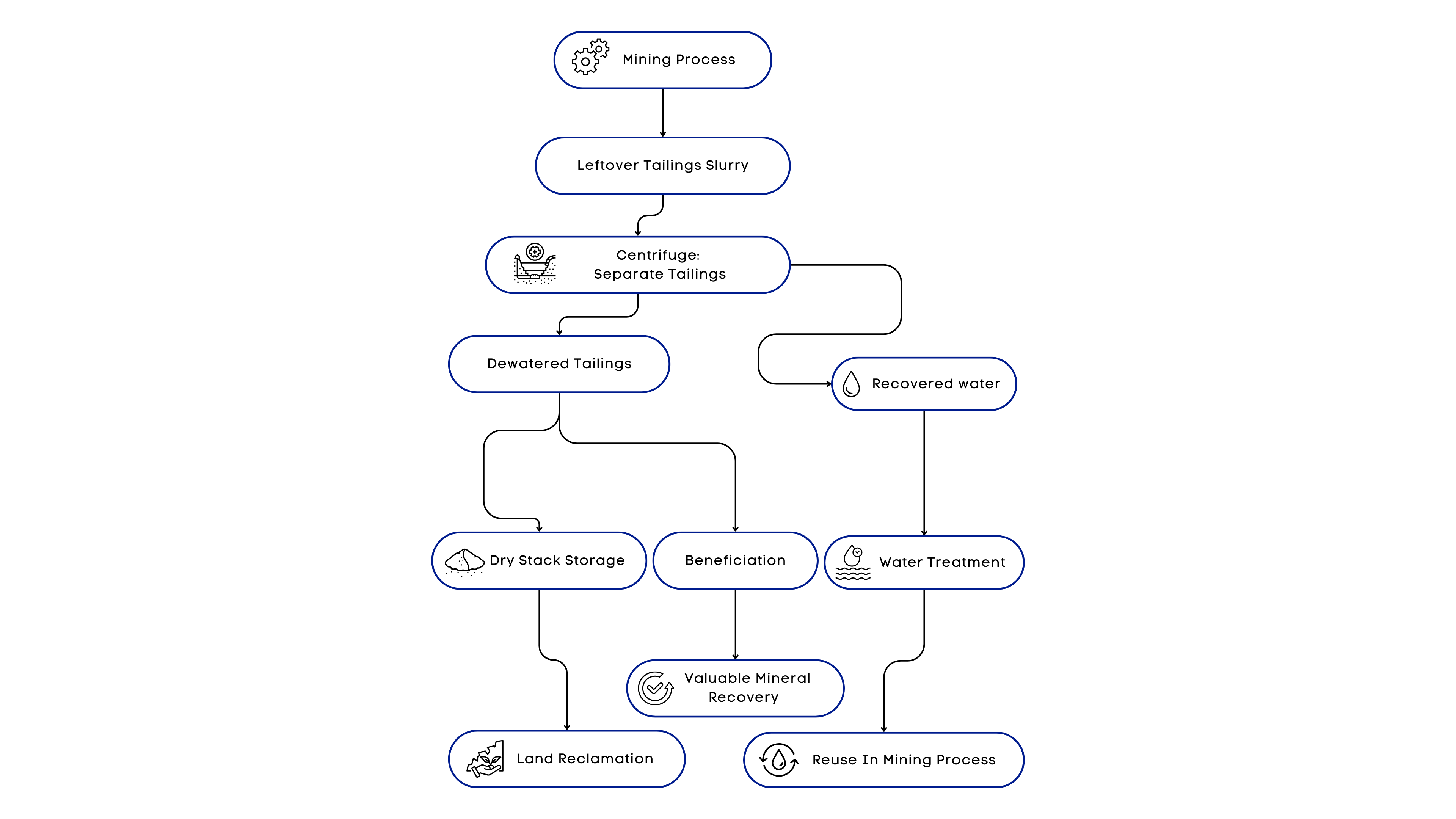

In the mining industry, responsible tailings management is crucial for environmental protection and sustainability. Traditional tailings dams pose significant environmental risks, including potential dam failures, contamination of water sources, and long-term land disturbance. At Sacor, our advanced decanter centrifuge solutions offer a superior and sustainable alternative, enabling effective tailings management while minimizing or even eliminating the need for tailings dams and their associated environmental impact.

Advantages and Benefits:

Minimized or eliminated need for tailings dams, reducing environmental risks

Improved stability and safety of any remaining tailings dams

High water recovery rates for reuse, reducing freshwater consumption

Reduced transportation and disposal costs due to lower tailings volume

Continuous operation and high throughput capacity for efficient waste management

Our centrifuges are engineered to handle the full spectrum of base metal processing, from iron ore concentration and dewatering to wastewater treatment and tailings management for metals like copper, aluminium, nickel, zinc, and lead. By leveraging the power of centrifugal forces, our solutions deliver unparalleled separation performance, driving productivity and reducing your environmental footprint.

Tailings Dewatering and Water Recovery

Sacor’s decanter centrifuges are employed for the dewatering of tailings, separating the solid and liquid components of the mining waste stream with unparalleled efficiency. Our centrifuges offer exceptional dewatering capabilities, recovering up to 85% of the water from tailings for reuse in mining operations or processing plants. This significantly reduces the volume of tailings, minimizing or eliminating the need for tailings dams and their associated footprint. Additionally, by reducing the moisture content of the tailings, the stability and safety of any remaining tailings dams are improved, mitigating the risk of dam failures.

Our centrifuges operate continuously and offer high throughput capacity, ensuring efficient waste management. By reusing the recovered water, freshwater consumption and associated costs are reduced, contributing to sustainable mining operations. Furthermore, the reduced volume of tailings minimizes transportation and disposal costs.

Tailings Treatment and Resource Recovery

Sacor’s centrifuges can be used for the treatment and separation of tailings, enabling the recovery of valuable minerals and metals, as well as the isolation of hazardous materials. Our centrifuges efficiently separate and recover valuable resources from the tailings, improving resource utilization and reducing waste. Additionally, hazardous substances are isolated and contained, minimizing environmental contamination.

Advantages and Benefits:

Efficient recovery of valuable minerals and metals from tailings

Isolation and containment of hazardous substances

Improved compliance with environmental regulations and sustainability goals

Potential for reuse or safe disposal of treated tailings components

The recovery of valuable resources and the proper treatment of tailings improve compliance with environmental regulations and support sustainability goals in the mining industry. Treated tailings components can be safely disposed of or potentially reused, further reducing the environmental impact of waste management operations.

Tailored Solutions for Sustainable Tailings Management

At Sacor, we understand the unique challenges and environmental concerns associated with tailings management in the mining industry. Our team of experts will work closely with you to design tailored centrifuge solutions that meet your specific requirements, whether you’re operating a tailings dam, managing waste from mineral processing operations, or addressing tailings-related challenges in various mining sectors.

Our centrifuge solutions are designed to be robust, reliable, and capable of handling the demanding conditions of tailings management operations in mining environments. By partnering with Sacor, you can demonstrate your commitment to sustainable practices, minimize the environmental impact of your mining operations, and ensure compliance with relevant regulations and industry standards.

Environmental Stewardship and Reduced Ecological Footprint

Sacor is dedicated to promoting environmental stewardship in the mining industry. Our centrifuge technology plays a crucial role in enabling responsible waste management practices, minimizing the ecological footprint of tailings management, and contributing to a more sustainable future for mining operations. By choosing Sacor’s solutions, you can significantly reduce or even eliminate the need for tailings dams, mitigate the risks associated with dam failures, and minimize the long-term land disturbance caused by traditional tailings management methods.

Through the exceptional water recovery capabilities of our centrifuges, you can achieve a closed-loop system, where the majority of the water is recovered and reused, reducing freshwater consumption and minimizing the discharge of contaminated water into the environment. By partnering with Sacor, you can demonstrate your commitment to environmental protection while achieving operational efficiency, resource recovery, and long-term sustainability in your mining operations.

Moreover, Sacor’s decanter centrifuges offer a superior alternative to traditional tailings dams by providing a more compact and efficient solution for tailings management. Unlike tailings dams, which require vast areas of land and pose significant environmental risks, our centrifuges have a smaller footprint and enable effective dewatering and separation of tailings within a controlled environment. This minimizes the risk of dam failures, reduces land disturbance, and offers a more sustainable approach to managing mining waste.

Our expert team is ready to assist you in finding the perfect centrifugal separation solution for your needs.